The first syntactic foam was developed in 1955 by the Bakelite Company of New York, and hailed as “A plastic foam, which promises to cut the partial cost of boat and airplane construction as much as 50%” [1]. It offered strength, insulation and tuneable properties in a lightweight material.

Syntactic foams are materials made up of hollow microspheres (commonly of glass, ceramic or plastic) held in a polymer matrix. The strength and buoyancy of syntactic foams has led to their widespread use in marine applications, their sound absorbing properties find uses in acoustic applications, and they have even been used in World Cup footballs due to their low density and elastic recovery [2,3].

The mechanical behaviour of materials can be defined in terms of stress (the force applied to the material per unit area) and strain (the deformation in the material in response to stress).

Viscoelastic materials combine the behaviours of viscous fluids and elastic solids when deformed. A plot of stress vs strain shows hysteresis, where the unloading (reverse) curve follows a different path to the loading (forward) curve, because some energy is lost to the system as heat:

- Elastic behaviour.

- Crushing of the microspheres (a region of low stiffness).

- Densification: the cavities fill up with debris from the crushed microspheres.

Stages 2 and 3 correspond to catastrophic damage to the microspheres, so glass microspheres are inappropriate for applications where foams will be under high strain.

Where plastic microspheres are used, the response of the material to compression also has three stages, but with less definition in-between:

- A small region of elastic behaviour.

- Buckling of the microsphere walls (a low stiffness region).

- Densification: the microsphere walls begin to touch.

The mechanical properties of syntactic foams with glass microspheres are well documented, but less work exists on plastic microsphere syntactic foams.

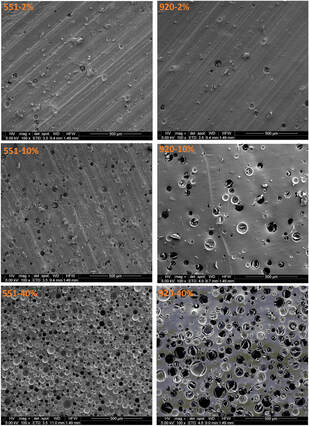

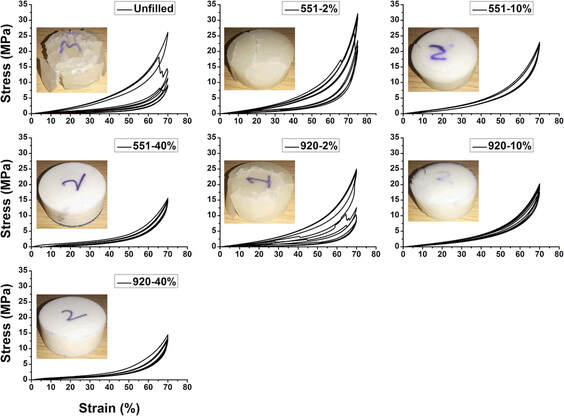

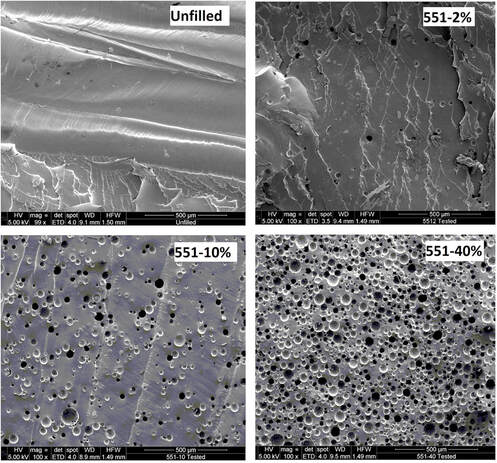

In this study we manufactured and tested polyurethane (PU) syntactic foams containing two grades of polymer microsphere. The foams contained a 2%, 10% or 40% volume of microspheres.

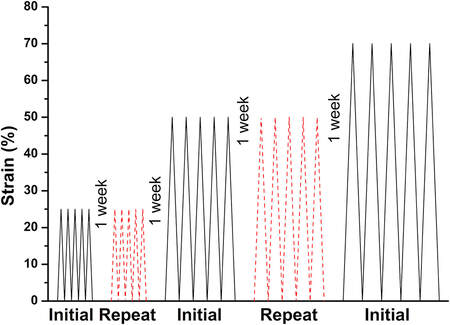

After 1 week, the samples were re-tested. They showed the same behaviour and little or no change in thickness, indicating that they had fully recovered from the previous testing.

Read the full article here: doi.org/10.1016/j.compositesb.2020.107764

[1] Plastic Foam Developed for Boats and Planes, The Science News-Letter, 1955, 67(14), 213

[2] N. Gupta, S.E. Zeltmann, V.C. Shunmugasamy, D. Pinisetty Applications of polymer matrix syntactic foams, JOM, 2014, 66(2), 245-254

[3] For explanation of the anatomy of the 2014 Adidas Brazuca World Cup football: www.livescience.com/46299-microscopic-analysis-brazuca-world-cup-ball.html

RSS Feed

RSS Feed